Stainless steel strip made from 304, 316L, and 430 grades is precision cold-rolled with 2B, BA, or HL finishes. It offers tight tolerances, flatness, and ductility for electronics, medical, and precision stamping.

| Element | Content (%) |

|---|---|

| C | ≤0.07 |

| Cr | 18.0–20.0 |

| Ni | 8.0–10.5 |

| Mn | ≤2.0 |

| Si | ≤1.0 |

| P | ≤0.045 |

| S | ≤0.03 |

| N | ≤0.10 |

| Property | Value | Test Standard |

|---|---|---|

| Density | 7.93 g/cm³ | GB/T 7999 |

| Tensile Strength | ≥520 MPa | GB/T 228.1 |

| Elongation | ≥45% | GB/T 228.1 |

| Salt Spray Resistance (NSS) | 1000 h without red rust | ASTM B117 |

| Hardness (HV) | 150–200 (soft state) | GB/T 4340.1 |

Thickness: 0.05–3 mm (tolerance ±0.005–±0.03 mm by thickness grade)

Width: 10–1219 mm (slitting available, min width 10 mm)

Length: Coils (50–1000 m/coil) or sheets (cut-to-length)

Common Grades: 304, 316L, 430

Surface Finishes: 2B (cold-rolled), BA (bright annealed), brushed (HL)

Coil Feeding into Processing Machine

Parallel Coil Processing Lines

Coil Thickness Measurement

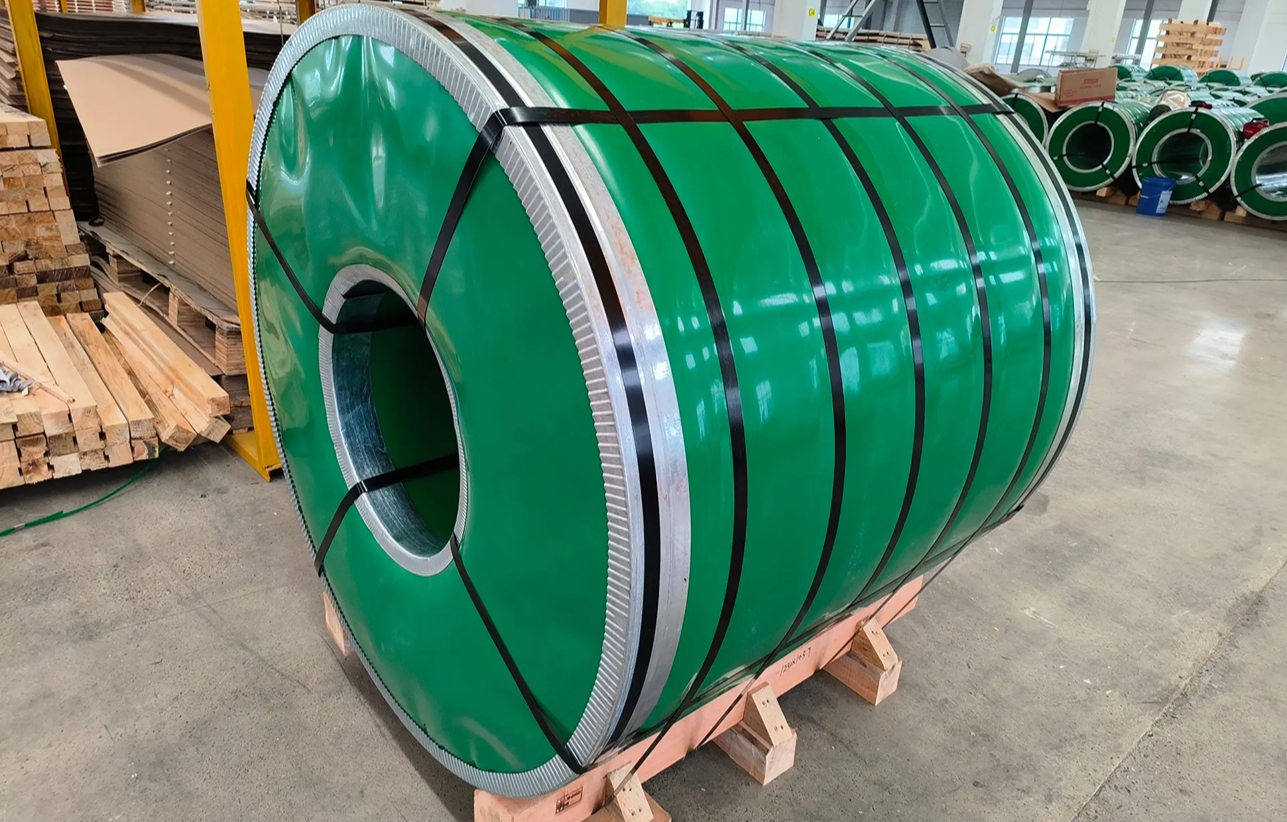

Single Coil Packaging

Factory Coil Storage

Truck Loading of Coils

Full range of precision stainless steel strip coil with global supply capabilities.

Fast delivery from stock or custom production runs.

Technical support and certifications to meet ASTM, EN, and GB standards.

Walmay will help match the right stainless product form and specification for your application, confirm quantities and packing needs, and provide requested documents based on order requirements.