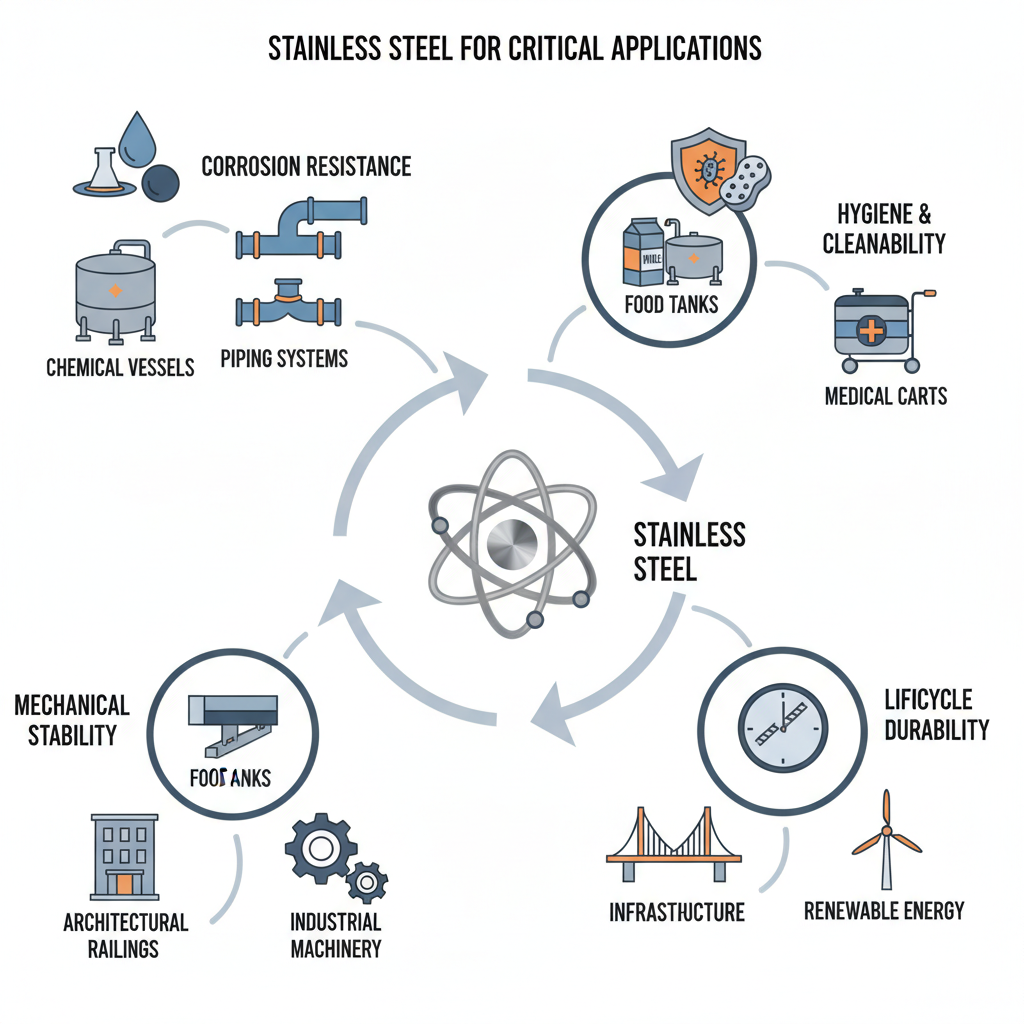

Stainless steel is used across industries not because it is shiny, but because it solves corrosion, hygiene, strength, and lifecycle cost problems that other metals cannot handle consistently.

Across industries, stainless steel is selected based on proven standards and long-term performance, not appearance or short-term cost. Organizations such as the World Stainless Association and ASTM standards consistently emphasize corrosion resistance, cleanability, mechanical stability, and lifecycle durability as the key drivers in critical environments.

This guide breaks down stainless steel applications by real use conditions and failure modes, so you can choose it for the right reasons and avoid common mistakes.

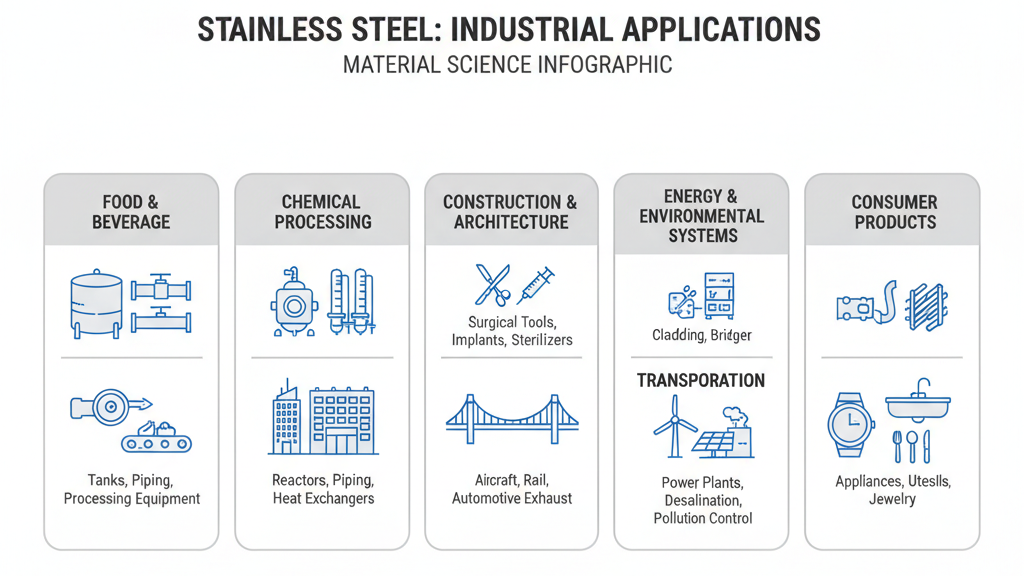

Stainless steel is the default material wherever cleanability and contamination control matter.

Typical applications

Why stainless steel works

Common grades

In chemical environments, many failures start with corrosion. Stainless steel reduces that risk when the grade matches the media and temperature.

Typical applications

Why stainless steel works

Common grades

Medical and pharma applications demand sterilization tolerance, repeatable surface condition, and low contamination risk.

Typical applications

Why stainless steel works

Common grades

In buildings, stainless steel is chosen for long-term durability and stable appearance, especially where coatings would be hard to maintain.

Typical applications

Why stainless steel works

Common grades

Stainless steel is used where heat, vibration, and corrosion combine, which is why automotive stainless steel is widely applied in exhaust systems and heat-affected vehicle components.

Typical applications

Why stainless steel works

Common grades

Energy and environmental systems stress materials through pressure, temperature cycling, and corrosive by-products.

Typical applications

Why stainless steel works

Common grades

Outside heavy industry, stainless steel is selected for stain resistance, durability, and stable finishes.

Typical applications

Why stainless steel works

Common grades

| Industry | Typical use | Primary benefit |

|---|---|---|

| Food and beverage | Tanks, conveyors, piping | Hygiene and corrosion resistance |

| Chemical | Vessels, pumps, heat exchangers | Chemical stability and service life |

| Medical and pharma | Instruments, carts, cleanrooms | Sterilization tolerance |

| Construction | Railings, cladding, fasteners | Low maintenance durability |

| Transportation | Exhausts, marine hardware | Heat and corrosion resistance |

| Energy and environment | Piping, pressure equipment | Performance under harsh service |

| Consumer | Appliances, cookware | Cleanability and finish stability |

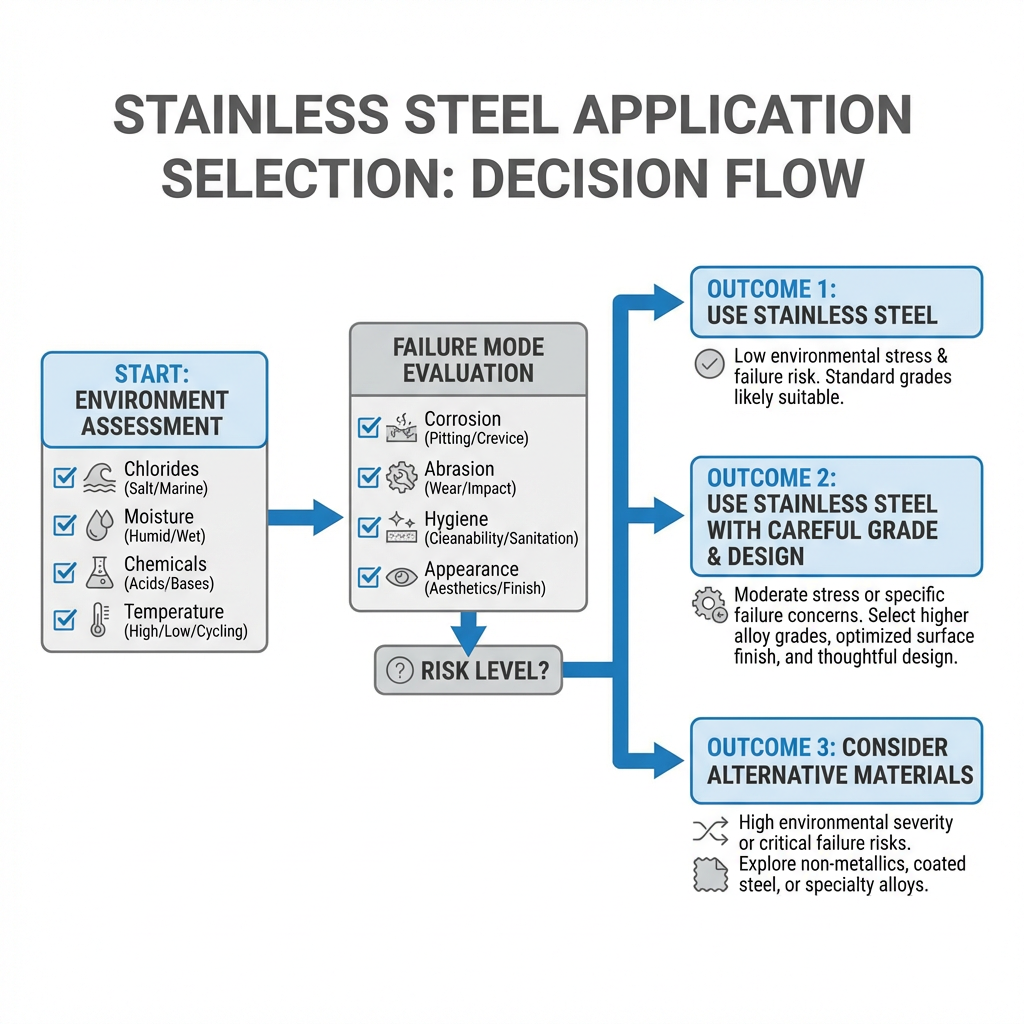

Stainless steel is a strong default, but it is not unbeatable. In real projects, the wrong grade in the wrong environment can fail faster than a protected carbon steel part.

If the site has chloride sources such as coastal air, de-icing salt, salt spray, brine, or bleach-based cleaning, standard grades can pit or crevice-corrode when the design traps moisture.

What to do instead

Use a chloride-suitable grade and design out water traps. In extreme exposure, consider higher-alloy options or system designs that prevent crevice conditions.

Many stainless failures are not material problems. They are geometry problems. Tight overlaps, unsealed lap joints, blind holes, gasket lines, and stagnant zones can defeat corrosion resistance even in mild environments.

What to do instead

Use cleanable geometry, improve drainage, reduce crevices, and treat joints as corrosion-critical features, not only mechanical features.

If the primary failure mode is abrasive wear from particles, slurry, sand, or grinding contact, stainless steel may lose thickness quickly even if it never rusts.

What to do instead

Use wear-focused materials or surface engineering, and reserve stainless steel for the sections where corrosion or hygiene is the real constraint.

Stainless steel can handle heat, but repeated thermal cycling can cause distortion, fatigue issues, and joint stress in thin sections or constrained assemblies.

What to do instead

Design for expansion, choose thickness and joint strategy deliberately, and select grades based on thermal and mechanical stability, not only corrosion resistance.

In dry indoor environments with low corrosion risk, stainless steel may be over-spec. Coated carbon steel can be more economical if maintenance access is easy and corrosion risk is controlled.

What to do instead

Decide using total cost over service life, including downtime, cleaning, inspection frequency, and replacement cost, not only material price.

One-sentence takeaway

Stainless steel performs best when the grade matches the environment and the design avoids crevices, trapped moisture, and wear-dominant contact.

Use this checklist to decide whether stainless steel is the right choice, what to prioritize, and where designs commonly go wrong.

Stainless steel is the right choice when corrosion resistance, hygiene, heat tolerance, or low-maintenance service life is the real constraint.

Decide in this order: confirm the environment, identify the dominant failure mode, then choose a suitable grade and design out crevices and water traps. This approach reflects the real applications of stainless steel across industries, helping you get the performance you paid for and avoid early failures caused by the wrong grade or geometry.

Walmay will help match the right stainless product form and specification for your application, confirm quantities and packing needs, and provide requested documents based on order requirements.