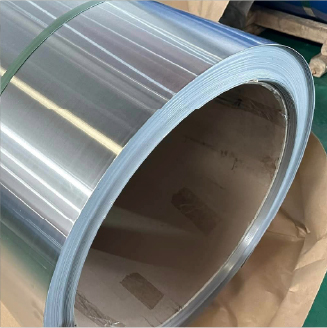

- Coils

- Sheets

- Pipes

- Bars

- Profiles

- Austenitic Grades

- Duplex Grades

- Ferritic Grades

- Martensitic Grades

- Precipitation Hardening Grades

- Cold Rolled

- Hot Rolled

A broad industrial choice when formability, weldability, and balanced corrosion resistance are required. Often specified for food-adjacent fabrication, moderate chemical exposure, and appearance-sensitive parts.

Surface finish affects corrosion performance, cleanability, appearance, and downstream work. If the finish is visible or functional, define it in the RFQ to avoid mismatch.

Value-added processing shortens time to production and reduces rework by delivering material closer to how your team uses it. Availability depends on product form, size, and order requirements.

Walmay will help match the right stainless product form and specification for your application, confirm quantities and packing needs, and provide requested documents based on order requirements.