Resistant to High-Temperature Oxidation, Suitable for Aircraft Engine Parts and Heat Exchanger Systems

| Element | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Cr | Ni | Ti |

|---|---|---|---|---|---|---|---|---|

| Content % | 0.08 | 1 | 2 | 0.035 | 0.03 | 17.0–19.0 | 9.0–12.0 | ≥5×C% |

Density: 7.93 g/cm³

Melting Point: 1398–1454 °C

Thermal Conductivity: 16 W/(m·K)

Mechanical Properties: Tensile strength ≥520 MPa, elongation ≥40%

Thickness: 0.5–6.0 mm (tolerance ±0.07 mm)

Width: 1000 / 1219 mm

Surface: 2B (cold-rolled annealed), customizable radiation-resistant coating

Coil Weight: 5–10 t/coil

Coil Feeding into Processing Machine

Parallel Coil Processing Lines

Coil Thickness Measurement

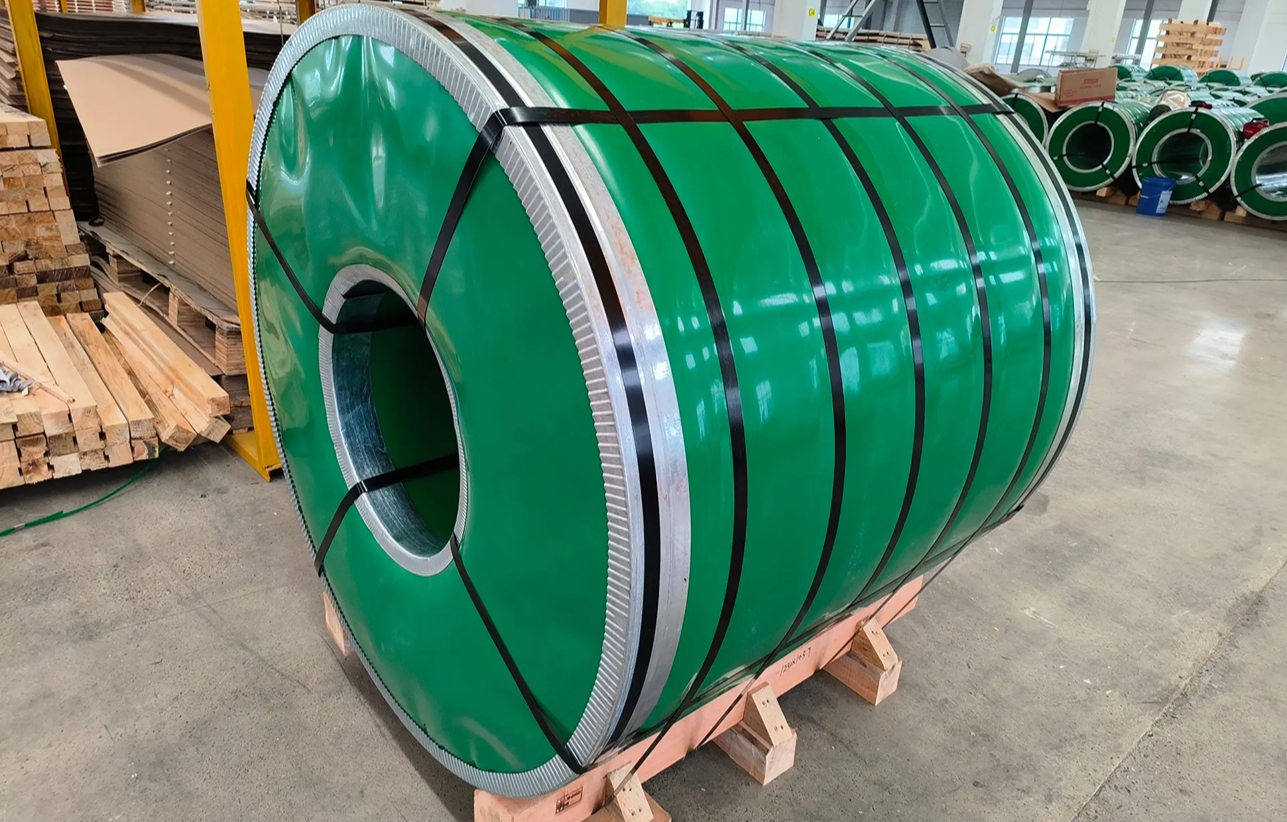

Single Coil Packaging

Factory Coil Storage

Truck Loading of Coils

Use ER321 welding wire; post-weld stabilization treatment required

Standard 1.0 mm × 1219 mm available; 3-day delivery

Walmay will help match the right stainless product form and specification for your application, confirm quantities and packing needs, and provide requested documents based on order requirements.