Ideal for Highly Corrosive Chemical Environments and Seawater Treatment Equipment

| Element | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|---|

| Content % | 0.03 | 1 | 2 | 0.035 | 0.03 | 18.0–20.0 | 11.0–15.0 | 3.0–4.0 |

Density: 8.0 g/cm³

Melting Point: 1350–1400 °C

Thermal Conductivity: 15.2 W/(m·K)

Mechanical Properties: Tensile strength ≥480 MPa, elongation ≥40%

Thickness: 0.5–6.0 mm (tolerance ±0.07 mm)

Width: 1000 / 1219 mm

Surface: 2B (cold-rolled annealed), customizable electro-polishing

Coil Weight: 3–8 t/coil, made-to-order

Coil Feeding into Processing Machine

Parallel Coil Processing Lines

Coil Thickness Measurement

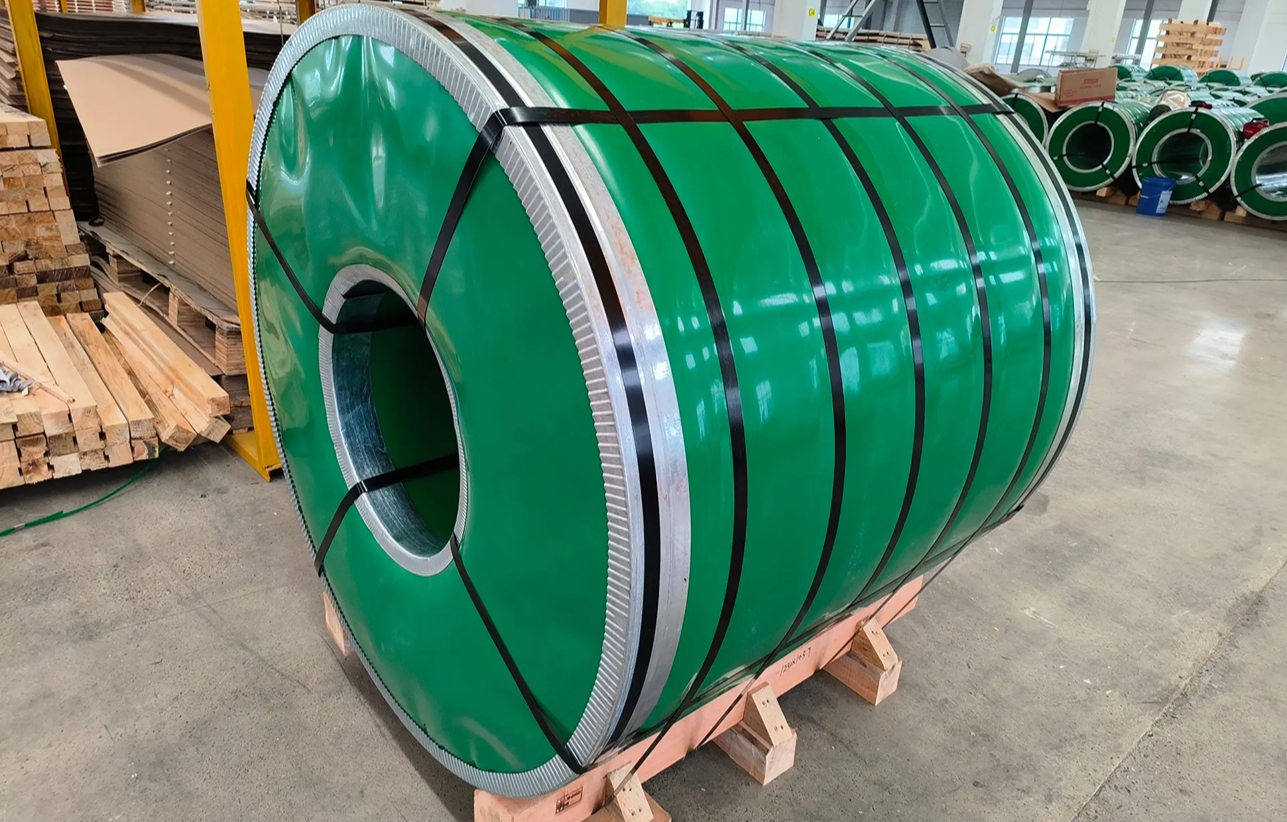

Single Coil Packaging

Factory Coil Storage

Truck Loading of Coils

Use ER317L welding wire; post-weld solution treatment required

Custom lead time 15–20 days, PMI inspection report provided

Walmay will help match the right stainless product form and specification for your application, confirm quantities and packing needs, and provide requested documents based on order requirements.