Widely Used in Kitchenware, Architectural Trim, and General Industrial Manufacturing

| Element | C | Si | Mn | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| Content (%) | ≤0.07 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.030 | 18.0–20.0 | 8.0–10.5 |

| Density | Melting Point | Thermal Conductivity | Coefficient of Thermal Expansion | Magnetic | |

|---|---|---|---|---|---|

| Physical Properties | 7.93 g/cm³ | 1398–1454 °C | 16 W/(m·K) at 20 °C | 17.2×10⁻⁶/°C (0–100 °C) | Non-magnetic (may become slightly magnetic after cold working) |

| Acid Corrosion Resistance | Intergranular Corrosion Resistanc | |

|---|---|---|

| Chemical Properties | Corrosion rate ≤0.01 mm/year in 5% citric acid solution at 25 °C. | No intergranular cracking observed after sensitization treatment at 650 °C and testing in copper sulfate–sulfuric acid solution. |

| Nominal Thickness (mm) | Width Tolerance ≤1000 mm | Width Tolerance >1000–1300 mm |

|---|---|---|

| 0.3–0.6 | ±0.04 mm | ±0.04 mm |

| 0.6–1.0 | ±0.05 mm | ±0.06 mm |

| 1.0–2.0 | ±0.08 mm | ±0.09 mm |

| 2.0–4.0 | ±0.13 mm | ±0.14 mm |

| 4.0–8.0 | ±0.17 mm | ±0.19 mm |

Coil Feeding into Processing Machine

Parallel Coil Processing Lines

Coil Thickness Measurement

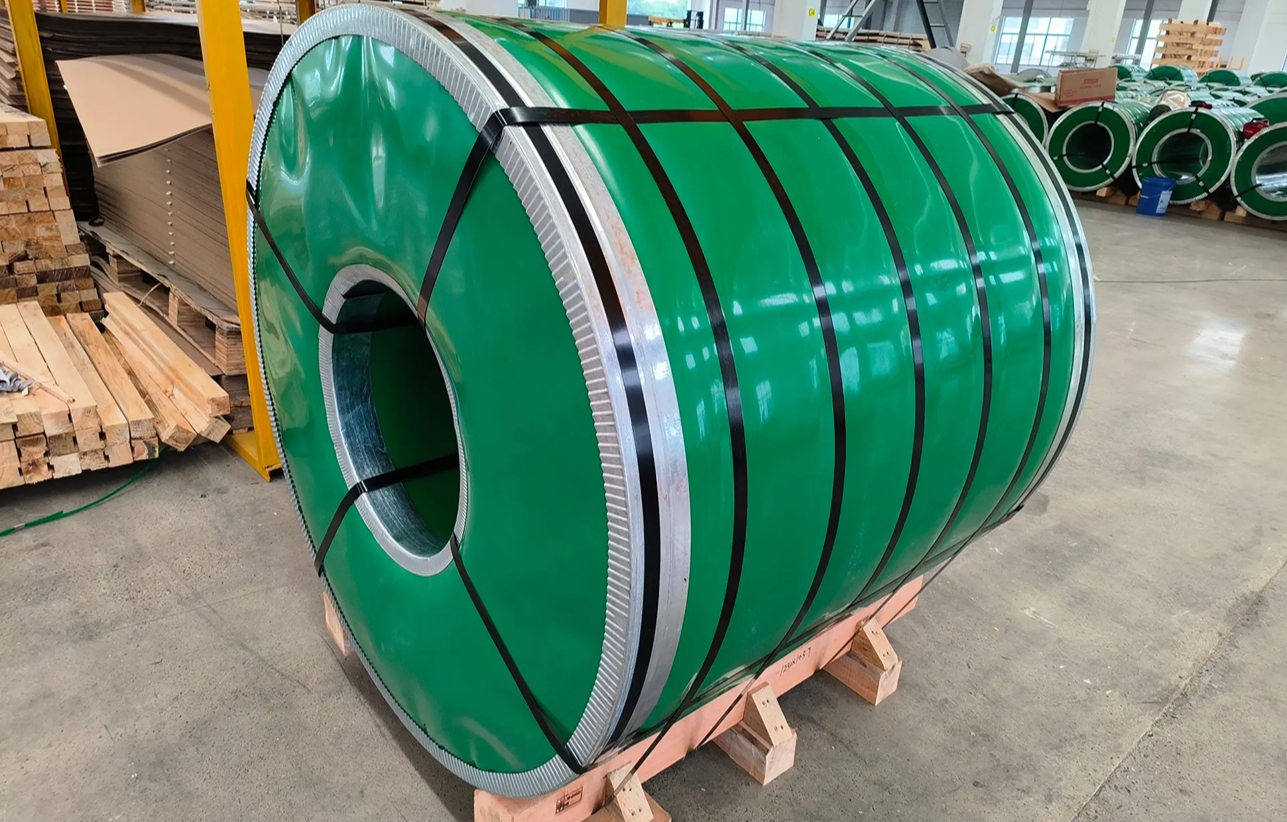

Single Coil Packaging

Factory Coil Storage

Truck Loading of Coils

Customizable surfaces such as BA (bright annealing), 8K mirror, and HL (brushed) are available; please specify in advance.

Packed with moisture-proof paper and galvanized iron sheets. Each coil weighs ≤10 tons. Wooden crates are required for fixing during sea transportation.

Regular specifications (0.5-3.0mm×1219mm) are fully stocked, with delivery within 48 hours; the customization cycle for special specifications is 15-20 days.

TIG welding is recommended, using ER308L welding wire. No preheating is required before welding; interpass temperature should be ≤150℃. Post-weld pickling and passivation are recommended.

Walmay will help match the right stainless product form and specification for your application, confirm quantities and packing needs, and provide requested documents based on order requirements.