The steel forming process is a cornerstone of modern manufacturing. From automotive panels and structural beams to appliances, pipes, and precision components, steel must be shaped accurately and efficiently to meet design and performance requirements. Rather than removing material, steel forming reshapes metal through controlled force, improving material utilization and production efficiency.

This article explains what the steel forming process is, the main forming methods used in industry, how steel properties affect formability, and how manufacturers choose the right forming technique for each application.

The steel forming process refers to a group of manufacturing methods that shape steel by applying mechanical force without cutting or melting the material. During forming, steel undergoes plastic deformation, meaning it permanently changes shape while retaining its mass and internal continuity.

Steel forming is widely used because it:

Steel can be formed in hot, warm, or cold conditions depending on the process, thickness, and required properties.

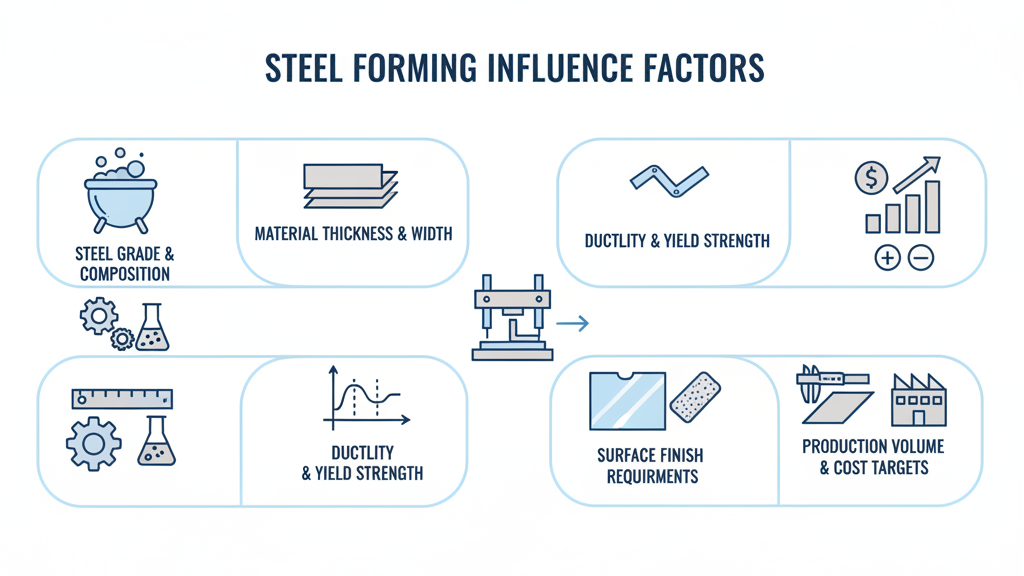

Before selecting a steel forming process, manufacturers must consider several material and design factors:

These factors determine whether steel should be hot formed, cold formed, or shaped using specialized techniques.

Steel forming processes are broadly categorized based on temperature and deformation method.

In hot forming, steel is heated above its recrystallization temperature, making it softer and easier to shape.

Hot-formed steel is commonly used for structural beams, rails, heavy plates, and large industrial components.

The cold forming process shapes steel at or near room temperature. This process increases strength through strain hardening while providing better surface finish and dimensional accuracy.

Cold-formed steel is widely used in automotive panels, appliances, furniture, electrical enclosures, and light-gauge construction.

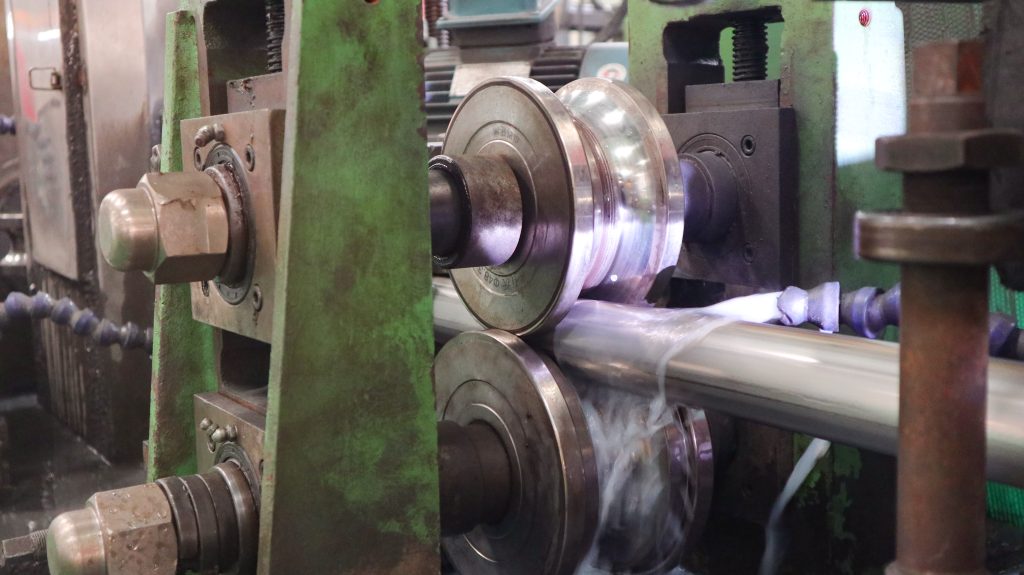

Roll forming is a specialized cold forming process where steel strip or coil passes through a series of rollers that gradually shape it into a desired profile.

Roll forming is ideal for long parts with consistent cross-sections and tight tolerances.

Stamping uses dies and presses to cut, bend, or draw steel sheet into complex shapes.

Stamping is a high-speed steel forming process commonly used in automotive, appliance, and electronics manufacturing.

Forging shapes steel using compressive force, often with hammers or presses.

Forged steel parts are used in crankshafts, gears, connecting rods, and heavy machinery components.

Not all steel forms the same way. Key properties influencing steel forming include:

Annealed steel is often preferred for demanding forming operations because it offers improved ductility and reduced internal stress.

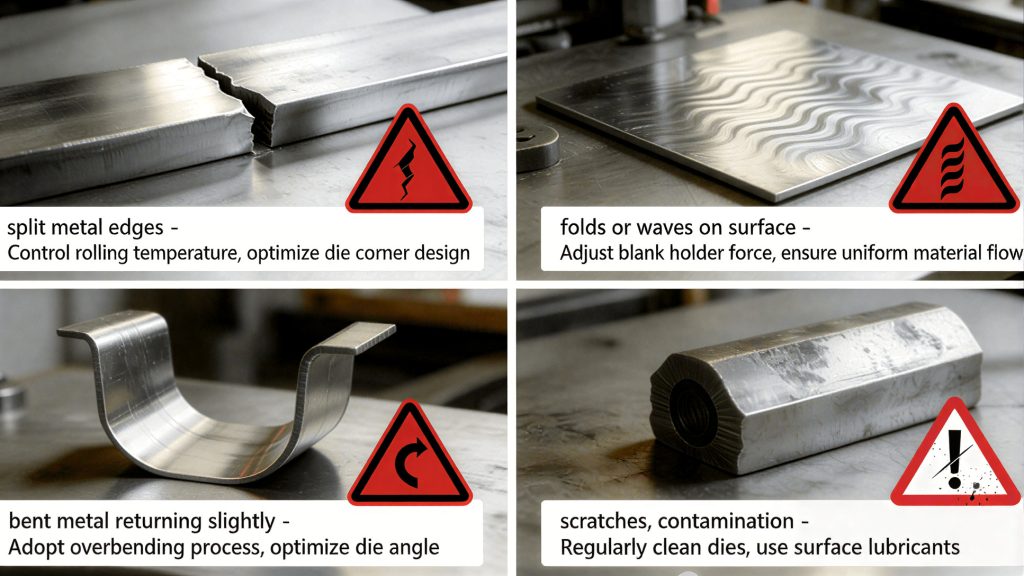

Steel forming processes can introduce defects if not properly controlled:

Careful material selection, tooling design, lubrication, and process control help minimize these issues.

Steel forming supports a wide range of industries:

Each application relies on specific steel forming methods to balance strength, appearance, cost, and performance.

The steel forming process enables manufacturers to shape steel efficiently while preserving strength, minimizing waste, and achieving consistent quality. From hot rolling and forging to cold rolling, stamping, and roll forming, each method serves a specific role in modern industry.

By understanding how steel properties interact with forming techniques, engineers and buyers can select the right process to improve performance, reduce costs, and ensure reliable production across the entire product lifecycle.

Walmay will help match the right stainless product form and specification for your application, confirm quantities and packing needs, and provide requested documents based on order requirements.