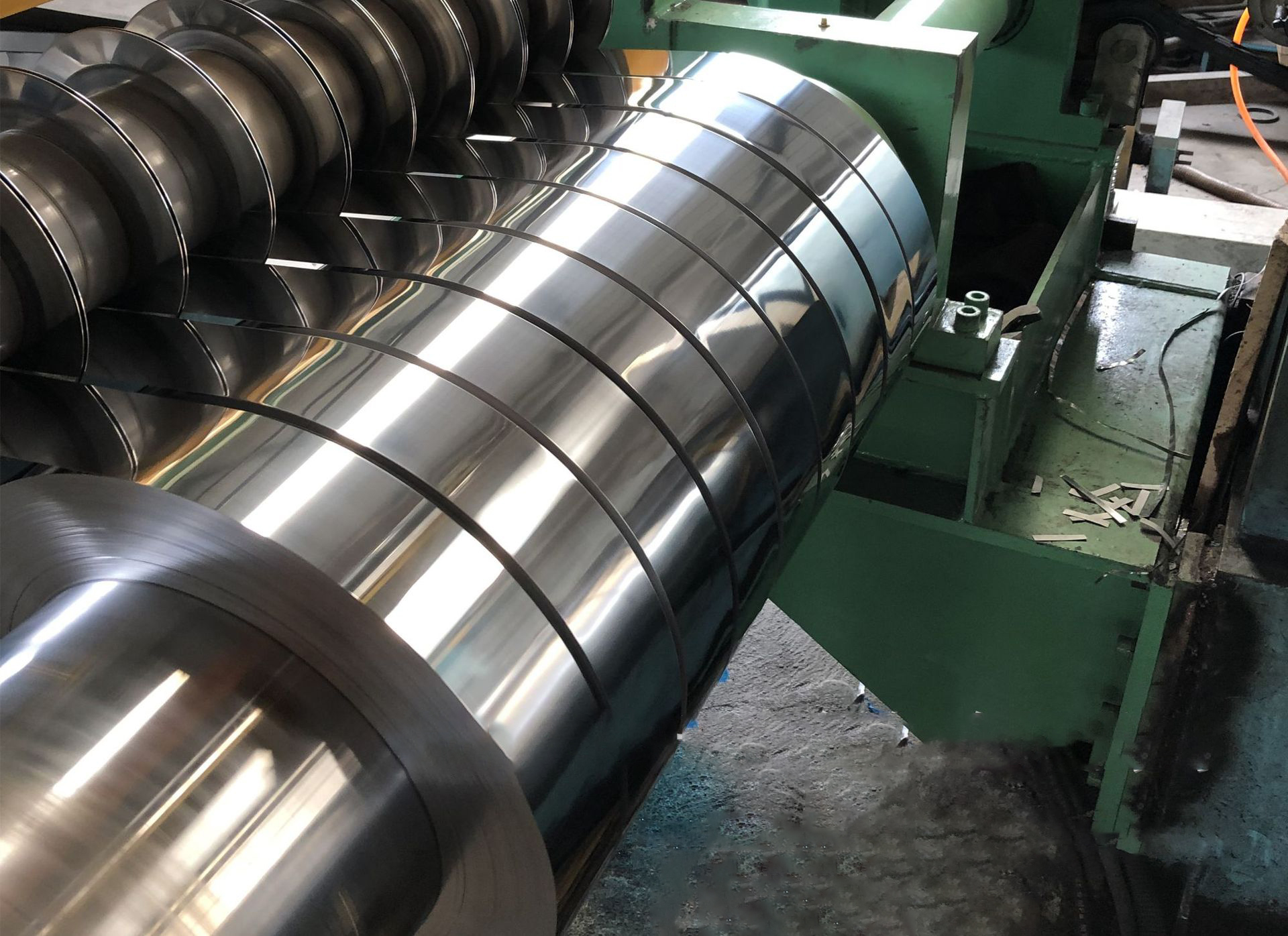

- Coils

- Sheets

- Pipes

- Bars

- Profiles

- Austenitic Grades

- Duplex Grades

- Ferritic Grades

- Martensitic Grades

- Precipitation Hardening Grades

- Cold Rolled

- Hot Rolled

Cold rolled and hot rolled coils with thickness from 0.2–6.0 mm and consistent width control. Bright annealed and precision-slitted options ensure stable quality across grades 304, 316L, 430, and 201.

Widely used in automotive trim, appliances, construction, and cable armoring. Finishes like 2B, BA, and HL combine durability with decorative appeal, supported by protective film packaging.

Each batch is verified with spectrometer testing and supplied with Mill Test Certificates (EN 10204 3.1). Compliance with ASTM, EN, JIS, and GB/T standards ensures reliable performance and global acceptance.

| Grade | Thickness Range (mm) | Width Range (mm) | Surface Finishes | Coil ID / OD | Max Coil Weight | Typical Tolerance |

|---|---|---|---|---|---|---|

| 304 | 0.2 – 6.0 | ≤ 1500 | 2B, BA, HL | ID 508 / 610 mm, OD ≤ 2000 mm | ≤ 20 MT | Width ±0.1 mm / Thickness ±5% |

| 316L | 0.3 – 6.0 | ≤ 1500 | 2B, BA, HL | ID 508 / 610 mm | ≤ 20 MT | Width ±0.1 mm / Thickness ±5% |

| 430 | 0.3 – 3.0 | ≤ 1219 | 2B, BA, HL | ID 508 / 610 mm | ≤ 15 MT | Width ±0.1 mm / Thickness ±5% |

| 409L | 0.3 – 3.0 | ≤ 1219 | 2B, BA | ID 508 / 610 mm | ≤ 15 MT | Width ±0.1 mm / Thickness ±5% |

| Duplex 2205 | 0.5 – 5.0 | ≤ 1500 | 2B, HL | ID 508 / 610 mm | ≤ 20 MT | Width ±0.1 mm / Thickness ±5% |

Recommended Grades: 304, 316L

Surface Finishes: 2B, BA

Reason: Corrosion resistance, easy to clean

Recommended Grade: 316L

Surface Finish: 2B

Reason: Excellent pitting and chloride resistance

Recommended Grades: 409L, 430, 310S

Surface Finishes: BA, HL

Reason: Heat resistance and cost efficiency

Recommended Grades: 304, 316L

Surface Finishes: 2B, HL

Reason: Structural strength and weather resistance

We provide customized coil processing services to match your production needs:

Slitting: precision ±0.1 mm

Cut-to-Length: flat sheets with consistent tolerances

Polishing & Brushing

Edge Trimming: Mill edge or Slit edge

Protective Film: applied on BA/HL surfaces for transport & fabrication

Walmay will help match the right stainless product form and specification for your application, confirm quantities and packing needs, and provide requested documents based on order requirements.