Stainless steel is often described as “durable” and “corrosion-resistant,” but these labels barely scratch the surface. Behind its clean appearance lies a complex, engineered family of alloys that enable modern architecture, food processing, marine systems, medical equipment and energy infrastructure.

This upgraded guide reveals essential facts about stainless steel that go deeper than the usual list of interesting trivia—giving you insight into its chemistry, performance, real-world applications and selection considerations.

The hallmark of stainless steel is its ability to resist rust. This is achieved through a chromium-rich passive film that forms naturally on the surface. When scratched or damaged, the film regenerates instantly in the presence of oxygen.

This self-healing mechanism is why stainless steel performs reliably in food processing lines, outdoor architecture and chemical environments where carbon steel would fail quickly.

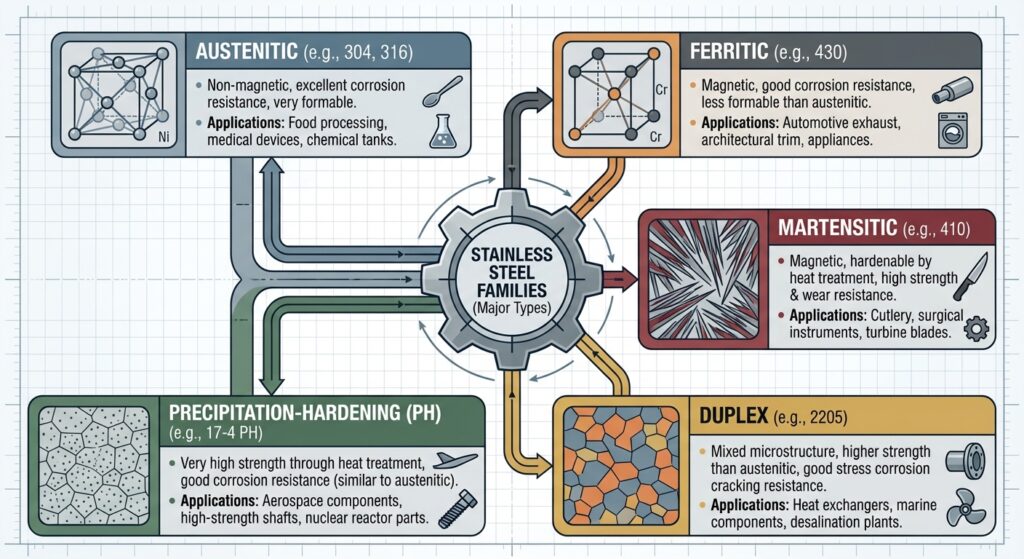

One of the most overlooked facts about stainless steel is its diversity. The term covers a broad family of alloys, including austenitic, ferritic, martensitic, duplex and precipitation-hardening grades.

Each category is engineered for specific performance: formability, heat resistance, toughness, chemical resistance or high strength. Selecting the right grade is more important—and more technical—than many buyers realise.

Engineering trends show increasing demand for duplex stainless steels due to their superior strength-to-weight ratio and enhanced corrosion resistance.

For coastal projects, desalination, chemical plants and energy systems, duplex grades offer higher value than standard 304/316—often reducing material thickness and lifecycle costs.

Brushed, mirror, bead-blasted or patterned finishes are more than aesthetic preferences. They influence cleanability, hygiene, fingerprint resistance, reflectivity, friction and even corrosion behaviour.

This is why industries such as food equipment, pharmaceuticals and architecture specify finishes with the same seriousness as they specify grades.

Depending on the grade, stainless steel can operate from cryogenic conditions to elevated temperatures beyond 800°C.

Austenitic grades excel at low-temperature toughness, while heat-resistant grades such as 310/309 maintain strength at high temperature.

This versatility makes stainless steel indispensable in furnaces, exhaust systems, heat exchangers and industrial kilns.

Many stainless steels can significantly increase yield strength through cold rolling, drawing or stamping.

This enables manufacturers to reduce material thickness, lower weight and improve mechanical performance—without compromising corrosion resistance.

Unlike coatings or plated materials, stainless steel is fully recyclable and does not degrade during remelting. The global supply chain already relies heavily on recycled scrap.

This circularity, combined with long service life, makes stainless steel one of the most environmentally responsible material choices.

Like all metals, stainless steel has thermal expansion characteristics that must be considered in long pipelines, architectural panels or heat-exposed structures.

Proper allowances prevent warping, stress accumulation or “oil-canning” in sheet-metal applications.

A common misconception is that stainless steel never requires upkeep.

In reality, contaminants such as chlorides, metal shavings, and industrial residues can compromise the passive film. Routine cleaning—especially in marine or factory environments—is essential for long-term durability.

Welding can alter corrosion resistance if heat input is not controlled or if the wrong filler metal is used.

For critical applications such as tanks, pipelines and hygienic equipment, proper welding procedures (e.g., purge welding, low-carbon grades, post-weld cleaning) are as crucial as grade selection.

Beyond industrial use, stainless steel appears in unexpected applications like odor-neutralizing soap bars, conductive glove fibers, precision medical tools and antimicrobial surfaces.

Its combination of hygiene, durability and stability makes it a preferred material for both consumer and professional equipment.

While global markets differ, several universal trends are shifting stainless steel requirements:

These trends indicate that stainless steel is not just a commodity—it is a strategic material choice.

Selecting stainless steel is not just about corrosion resistance. A proper decision considers:

This selection process is why engineers and purchasing teams often consult material specialists rather than simply choosing 304 or 316 by habit.

Stainless steel is an exceptional material because of its engineered versatility, self-healing corrosion resistance, extensive grade families and sustainability advantages. From architectural structures to food equipment to chemical systems, it delivers reliability under conditions where most metals fail. For any questions or guidance, you can get in touch with us.

By understanding these deeper facts about stainless steel, businesses can choose the right grade, finish and fabrication method—achieving higher performance, longer service life and better long-term value.

Walmay will help match the right stainless product form and specification for your application, confirm quantities and packing needs, and provide requested documents based on order requirements.