Stainless steel is renowned for its corrosion resistance, durability, and aesthetic appeal. But a common question arises among engineers, hobbyists, and industrial users alike: can stainless steel be magnetised? Understanding when and how stainless steel becomes magnetised—and what that means for its applications—is key for designers, fabricators, and buyers. This guide explores the magnetic properties of stainless steel, the science behind magnetisation, and practical insights into using magnetised stainless steel in real-world scenarios.

Stainless steel is an alloy primarily made of iron, chromium, and often nickel, designed to resist rust and corrosion. Its structure and composition vary widely, resulting in different grades tailored to specific needs.

The question of whether stainless steel can be magnetised is important because magnetism affects:

Some users expect stainless steel to be non-magnetic due to its corrosion resistance, but the reality is more complex. Whether stainless steel can be magnetised depends on its internal crystal structure and chemical makeup.

Stainless steels are typically classified into five main groups based on their microstructure:

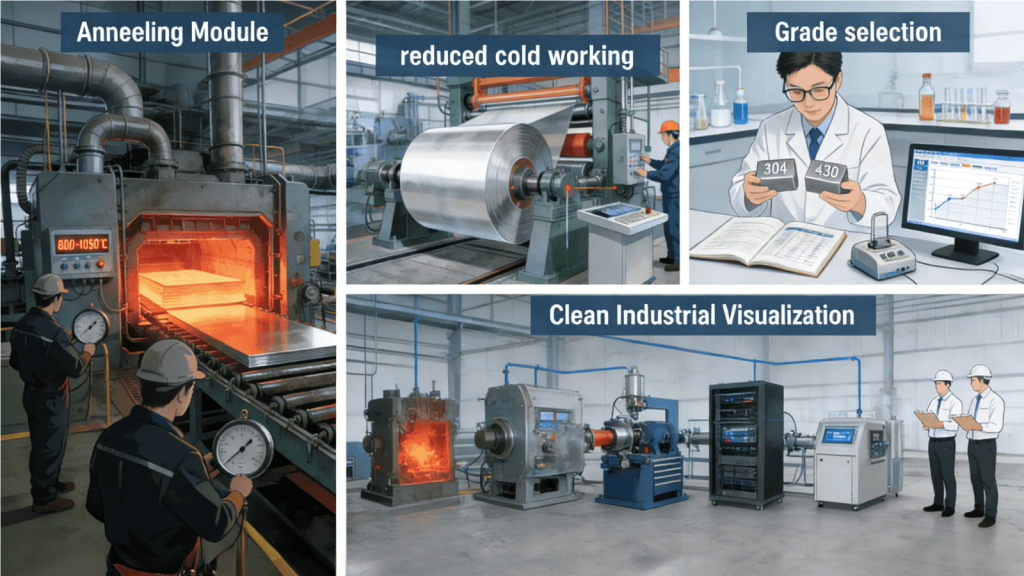

This is the most common stainless steel family, including grades like 304 and 316. Austenitic stainless steel has a face-centered cubic crystal structure that is generally non-magnetic in its annealed state. However, it can become slightly magnetic when cold worked (bent, stamped, or formed), as deformation induces some transformation to a magnetic phase.

Ferritic stainless steels (e.g., grade 430) have a body-centered cubic structure and are magnetic by nature. They do not transform when worked, maintaining consistent magnetic properties.

Martensitic grades (like 410 or 420) are magnetic and known for their hardness. These steels are commonly used in cutlery, blades, and industrial tools.

Duplex steels combine austenitic and ferritic structures, offering a balance of corrosion resistance and strength. Their magnetism falls between austenitic and ferritic steels, usually magnetic but less so than pure ferritic grades.

These grades have varied magnetic properties depending on their exact alloying elements and heat treatment.

Magnetisation is the process by which a material acquires a magnetic field or magnetic moment, usually by exposure to a magnetic source or mechanical deformation.

The magnetism observed in stainless steel is generally weak compared to iron or carbon steel, but it is enough to be detected by magnets or magnetic sensors.

Understanding the magnetism of stainless steel impacts several practical areas:

Cold working can cause parts to become magnetised, which may interfere with equipment sensitive to magnetic fields. Welding and heat treatments can also alter magnetic properties by changing the microstructure.

Non-magnetic stainless steel is preferred in medical devices and food processing to avoid interference with magnetic resonance imaging (MRI) or contamination from magnetic particles.

Magnetised stainless steel can affect inductive sensors or magnetic-based devices. Knowing the grade and condition of the steel is crucial when designing components for electronics.

Magnetism does not directly influence corrosion resistance, but the phases that cause magnetism can sometimes have different corrosion behaviors, especially in aggressive environments.

Simple magnet tests can help determine the magnetic nature of stainless steel:

More advanced testing, such as using magnetic permeability meters, can quantify the degree of magnetisation, useful for quality control in manufacturing.

If non-magnetic stainless steel is required, especially in critical applications:

Stainless steel can indeed be magnetised, but whether it becomes magnetised depends largely on its grade and mechanical history. Austenitic stainless steel is typically non-magnetic unless cold worked, while ferritic and martensitic stainless steels are inherently magnetic. The presence of magnetised stainless steel parts has practical implications across manufacturing, electronics, medical, and food industries.

Understanding these magnetic properties helps engineers and buyers select the right stainless steel grade and processing methods to ensure optimal performance and avoid unexpected magnetic effects. Rather than viewing stainless steel as uniformly non-magnetic, recognizing where and why magnetised stainless steel occurs is key to making informed decisions in design, fabrication, and application.

Walmay will help match the right stainless product form and specification for your application, confirm quantities and packing needs, and provide requested documents based on order requirements.