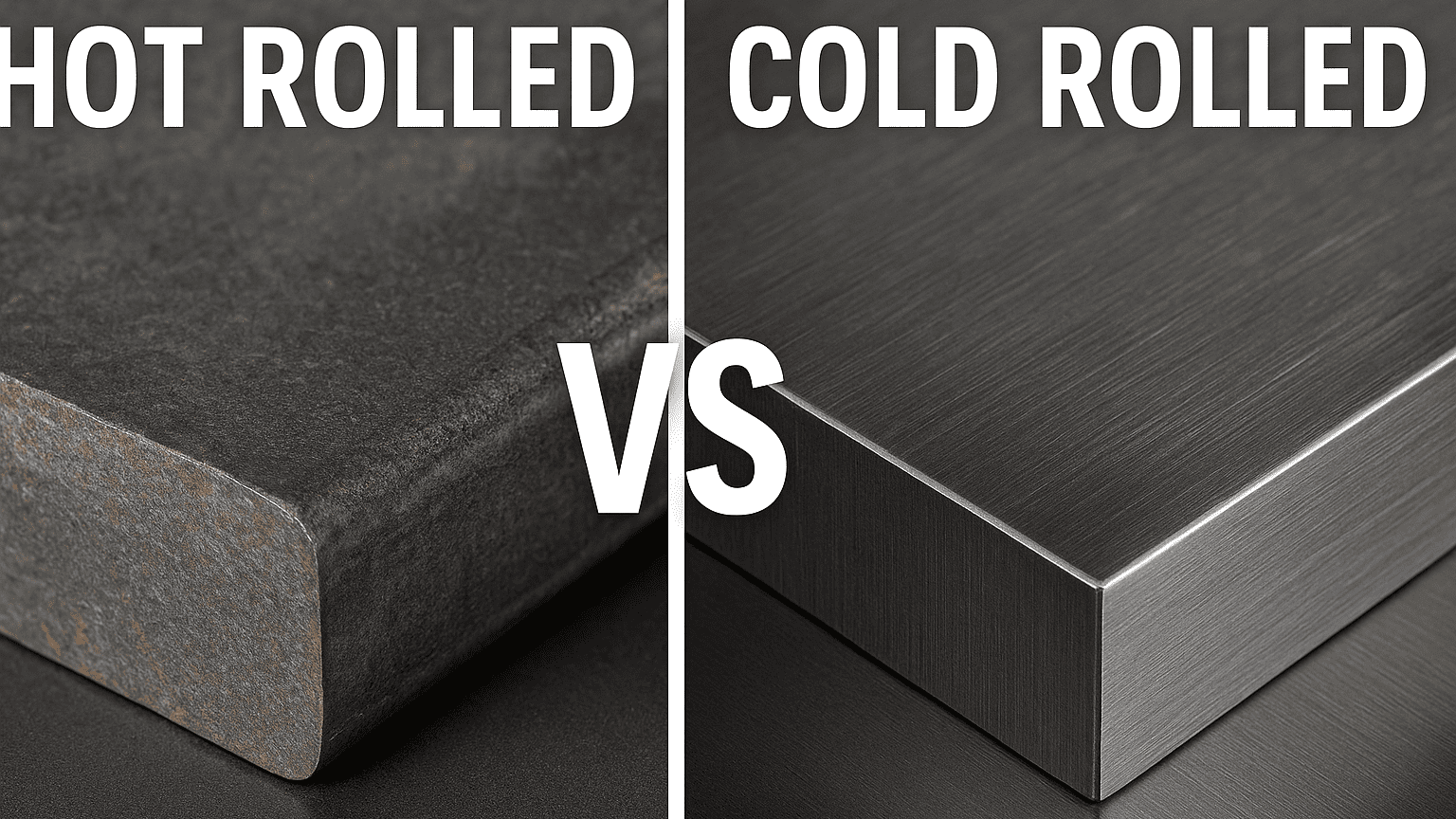

Steel is one of the most versatile materials in manufacturing, but not all steel is made the same way. The biggest distinction comes from how it’s processed — hot rolled vs cold rolled. These two terms describe temperature-based forming methods that greatly affect the steel’s strength, surface quality, and dimensional precision.

Understanding these differences helps you choose the right material for welding, machining, or structural fabrication.

Hot rolling means the steel is rolled above its recrystallization temperature — usually around 1,700°F (925°C). At this heat, the metal is soft and easy to shape, making it ideal for large-scale forming.

Structural beams, railroad tracks, agricultural equipment, frames, and general fabrication where precision isn’t critical.

Cold rolling takes hot rolled steel and further processes it at room temperature. The steel is re-rolled and sometimes annealed to achieve a smoother surface and tighter dimensional control.

Appliance panels, automotive parts, metal furniture, and precision-engineered components.

| Property | Hot Rolled Steel | Cold Rolled Steel |

|---|---|---|

| Processing Temperature | Above 1700°F (925°C) | Room temperature |

| Surface Finish | Rough, scaled | Smooth, bright |

| Dimensional Tolerance | Wide | Tight (precise) |

| Strength | Moderate | Higher (due to strain hardening) |

| Formability | Easier to form | Harder, may need annealing |

| Cost | Lower | Higher |

| Common Grades | ASTM A36, A1011 | ASTM A1008, A366 |

| Applications | Frames, beams, weldments | Panels, housings, appliances |

| Project Type | Best Choice | Reason |

|---|---|---|

| Structural frames, beams | Hot Rolled | Strength and cost efficiency |

| Precision housings, enclosures | Cold Rolled | Tight tolerances and smooth finish |

| Welded or fabricated structures | Hot Rolled | Less internal stress |

| Painted or coated parts | Cold Rolled | Clean surface improves adhesion |

| Bending/forming parts | Hot Rolled (pickled & oiled) | Easier forming |

| Machined components | Cold Rolled (annealed) | Stable and dimensionally accurate |

Q1: Is cold rolled steel stronger than hot rolled steel?

Yes. Cold rolling work-hardens the steel, increasing yield and tensile strength, but it also reduces ductility.

Q2: Can you weld cold rolled steel?

Absolutely. Just be aware of residual stress — use proper joint prep and consider preheating for thicker sections.

Q3: Why is hot rolled steel cheaper?

It skips the secondary cold finishing stage, reducing processing and energy costs.

Q4: What is HRPO steel?

Hot Rolled Pickled & Oiled steel — cleaned of scale and lightly oiled to prevent rust, offering better finish without the higher cost of cold rolled.

Q5: Does surface finish affect performance?

Yes. Smooth cold rolled surfaces are preferred for painted or plated components, while rougher hot rolled surfaces work fine for hidden or structural parts.

The difference between hot and cold rolled steel isn’t about which one is “better” — it’s about choosing the right material for your job. Hot rolled steel wins on cost and flexibility, while cold rolled steel excels in precision and aesthetics.

When you match the right rolling process to your tolerance, finish, and budget needs, you get the best balance of performance and efficiency.

Walmay will help match the right stainless product form and specification for your application, confirm quantities and packing needs, and provide requested documents based on order requirements.