Cold rolled steel is one of the most widely used steel products in modern manufacturing. Known for its smooth surface finish, precise dimensions, and improved strength, cold rolled steel is chosen for applications where accuracy, appearance, and consistent performance matter. Understanding what cold rolled steel is used for helps engineers, buyers, and fabricators select the right material for their projects.

This article explains the main uses of cold rolled steel, the industries that rely on it, and why it is preferred over other steel products in many applications.

Cold rolled steel is produced by further processing hot rolled steel at room temperature. After hot rolling and pickling to remove surface scale, the steel is passed through rollers to reduce thickness and improve surface quality. In many cases, cold rolled steel is annealed to restore ductility before final finishing.

This process results in steel with:

These characteristics directly influence how cold rolled steel is used.

Cold rolled steel is commonly used in manufacturing processes that require precision and high-quality finishes.

Cold rolled steel is widely used for:

Its uniform thickness and good formability make it ideal for high-speed stamping and deep drawing operations.

Many household and commercial appliances rely on cold rolled steel, including:

The smooth surface allows for easy painting, coating, or enameling.

Cold rolled steel is used for:

The material provides strength, dimensional stability, and a professional appearance.

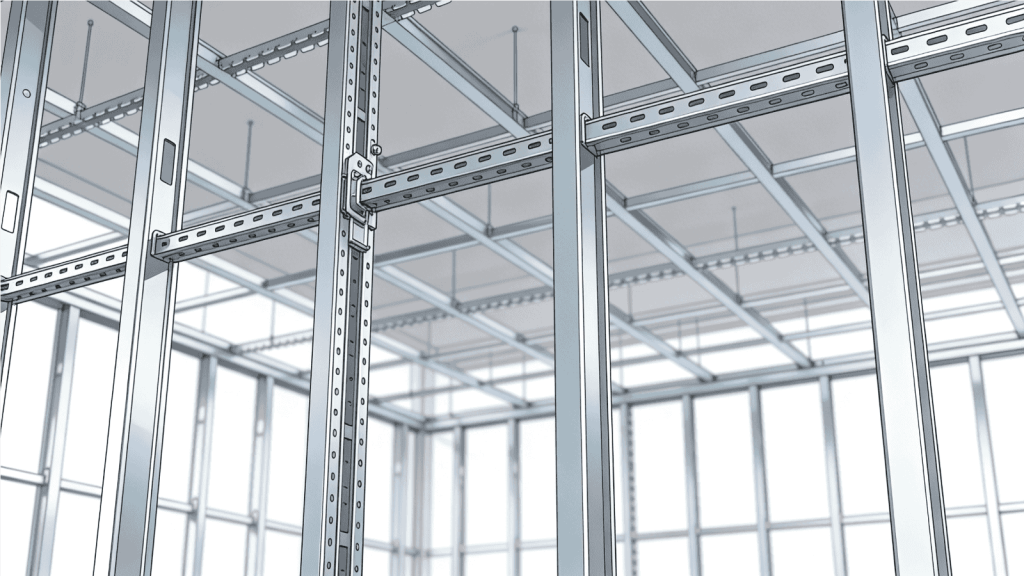

In construction, cold rolled steel is used primarily for light-gauge and precision components rather than heavy structural members.

Cold rolled steel is formed into:

These components benefit from consistent dimensions and predictable strength.

Cold rolled steel is often used for:

Its smooth surface supports high-quality finishes and coatings.

Cold rolled steel is commonly used in:

Its strength-to-thickness ratio allows for durable yet lightweight designs.

One of the most important uses of cold rolled steel is in precision forming and stamping.

Cold rolled steel is ideal for:

Cold rolled steel strip is also used to manufacture:

The consistent thickness improves weld quality and dimensional control.

Cold rolled steel is chosen over hot rolled steel when applications require:

Although it costs more than hot rolled steel, cold rolled steel often reduces downstream processing, rework, and finishing costs.

Cold rolled steel is used across automotive, appliance, construction, electrical, furniture, and precision manufacturing industries. Its smooth surface, precise dimensions, and enhanced strength make it ideal for visible parts, tight-tolerance components, and high-volume production.

Understanding what cold rolled steel is used for allows engineers and buyers to match material properties with real-world requirements, improving product quality, efficiency, and overall cost performance.

Walmay will help match the right stainless product form and specification for your application, confirm quantities and packing needs, and provide requested documents based on order requirements.