Annealing is a vital heat treatment process in the steel industry that profoundly affects the mechanical and physical properties of steel. Whether you’re working with carbon steel, alloy steel, or stainless steel, understanding the steel of annealing — the types of steel suitable for annealing and how the process changes steel — is essential for manufacturers, engineers, and metalworkers.

This article explores the science behind annealing steel, why it’s done, and how it enhances steel’s performance across various applications.

Annealing is a controlled heating and cooling process that softens steel, relieves internal stresses, and improves ductility and machinability. The steel is heated to a specific temperature where its crystalline structure changes, then cooled slowly to allow the formation of a more uniform and stable microstructure.

Annealing can be applied to many steel types, but its effects vary depending on the steel’s composition:

Low to medium carbon steels are commonly annealed to improve ductility and reduce hardness, making them easier to machine or form. Annealing is critical for steels that undergo cold working or require welding.

Alloy steels, containing elements like chromium, nickel, or molybdenum, are annealed to balance hardness and toughness. Precise annealing helps achieve desired strength levels while maintaining good ductility.

Certain stainless steels, particularly austenitic grades, are annealed to restore softness after cold working. Annealing also improves corrosion resistance by homogenizing the microstructure.

Steel’s microstructure determines its mechanical properties. Annealing transforms the microstructure by:

The result is a softer, more ductile steel that can be easily shaped and formed without cracking.

The annealing process generally involves:

Controlling the heating and cooling rates is critical to avoid defects such as warping or cracking.

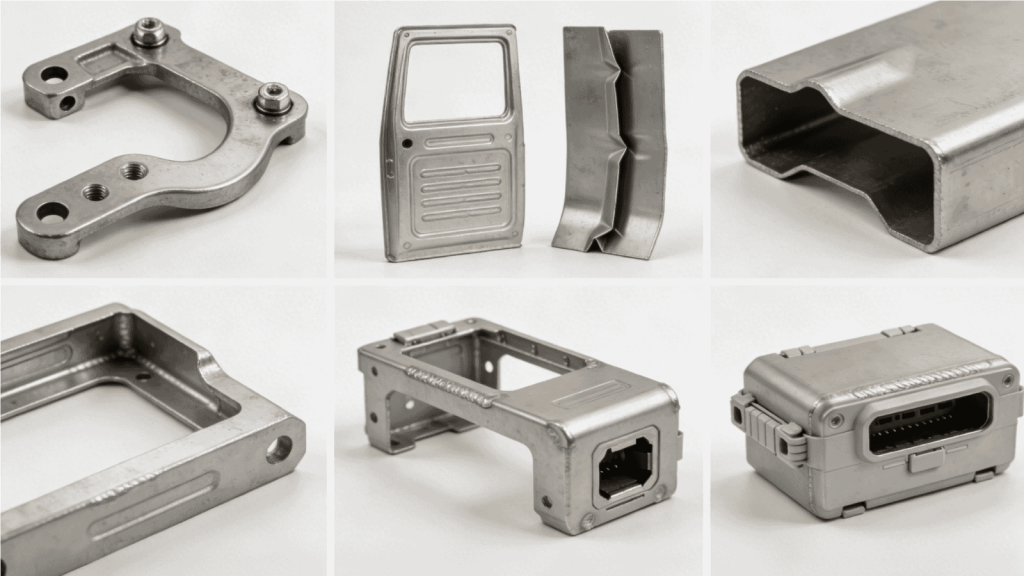

Annealed steel is used where softness, formability, and toughness are essential, including:

Understanding the steel of annealing means knowing how heat treatment tailors steel properties to specific needs. Whether you are working with carbon, alloy, or stainless steel, annealing enhances ductility, relieves stress, and improves machinability—making steel more versatile for modern manufacturing.

Choosing the right steel grade and annealing parameters ensures optimal performance, longevity, and cost-effectiveness in your projects.

Walmay will help match the right stainless product form and specification for your application, confirm quantities and packing needs, and provide requested documents based on order requirements.